The Latest Processing Technology in Wrought Iron Processing Industry -Pipe twisting machine

The Latest Processing Technology in Wrought Iron Processing Industry -Pipe twisting machine

1. Introduction about processing technology in metal craft processing business.

1.1 Brief overview of the wrought iron processing industry

The wrought iron processing industry involves the production of iron products using traditional forging techniques. These products include decorative items, furniture, and structural elements for buildings and other structures. The industry has a long history, dating back to the Middle Ages, and continues to be an important part of the global metalworking industry.

With the development of science and technology, especially the use of hydraulic and electric processing equipment after the second industrial revolution, processing equipment with electricity as the main energy source began to replace human work. Electric wrought iron machines become more and more important.

One of the most important developments in the wrought iron processing industry has been the adoption of hydraulic and electric processing equipment. These machines use hydraulic or electric power to manipulate iron pipes and create intricate shapes and designs. This has greatly improved the efficiency and precision of the production process, allowing companies in the industry to produce high-quality products more quickly and at a lower cost.

Additionally, the use of hydraulic and electric processing equipment has reduced the need for manual labor, allowing companies to operate with a smaller workforce. This has helped to reduce costs and improve the competitiveness of the industry.

Overall, the adoption of hydraulic and electric processing equipment in the wrought iron processing industry has been a key factor in its development and growth in recent years. It is expected to continue to play a crucial role in the industry’s future.

1.2 Importance of incorporating the latest processing technologies.

The incorporation of the latest processing technologies is crucial for the continued success of the wrought iron processing industry. These technologies allow companies to produce high-quality products more efficiently and at a lower cost, which is essential for competing in a global market.

In addition, the adoption of new processing technologies helps to improve the safety and working conditions of employees in the industry. It also allows companies to stay ahead of the competition and meet the changing needs of customers.

Overall, incorporating the latest processing technologies is essential for the long-term sustainability and growth of the wrought iron processing industry.

It is important to pay attention to the latest processing technologies in the wrought iron processing industry for several reasons.

Firstly, incorporating the latest technologies can help companies in the industry to improve their efficiency and productivity. This can lead to cost savings, higher profit margins, and greater competitiveness in the market.

Secondly, the use of the latest processing technologies can also improve the quality of the products produced by the industry. This can lead to increased customer satisfaction and the development of new markets for wrought iron products.

Lastly, staying up-to-date with the latest processing technologies can help companies in the industry to remain competitive in a rapidly changing market. This can ensure their long-term viability and success.

2. The hydraulic pipe twisting machine

2.1 What is Pipe twisting machine?

A pipe twisting machine for wrought iron is a type of machine that is used to twist pipes, typically as part of the manufacturing process. This machine is used to twist pipes in order to make them stronger and more durable. The process of twisting pipes can also be used to create specific patterns or designs on the surface of the pipes. Pipe twisting machines are commonly used in the construction and manufacturing industries to produce pipes for a wide range of applications.

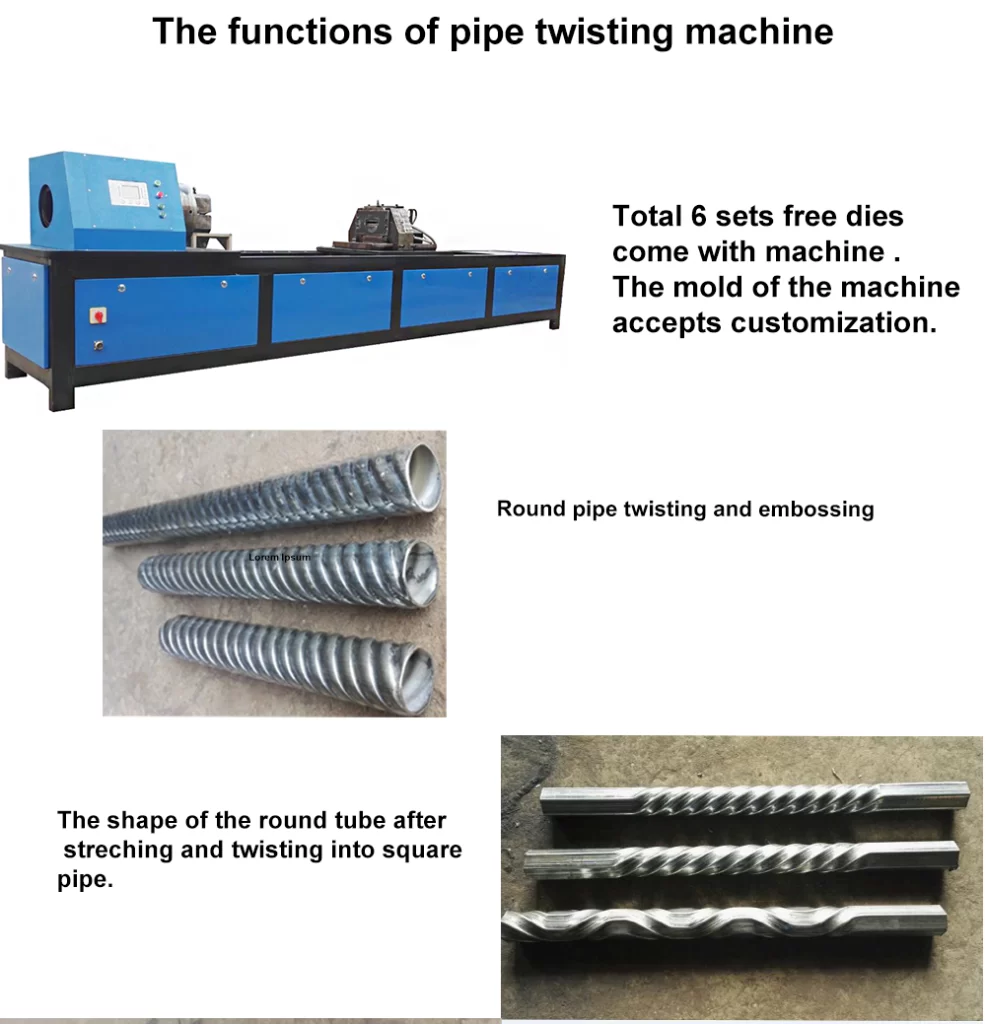

LC-JKLG60 Aotumatic Multi Function Round Pipe Twisting Machine

TECHNICAL PARAMETER

Model :LC-JKLG60

Processing material: Round tube≤Φ60mmx1.2mm

Dimensions of the finished product :

Round tube≤Φ60mmx1.2mm

Flat tube ≤ 60x30x1.2mm

Square tube≤15x15x1.2-60x60x1.2mm

Power: 7.5KW

For free dies :6sets

Voltage: 220V/380V/415V

Packing Dimension:800*1200*700mm

N.W. (kg): 1100 G.W. (kg): 1150

2.2 Description of the pipe twisting machine and its features

The hydraulic wrought iron tube twisting machine for steel pipe is a specialized piece of equipment used in the wrought iron processing industry. It consists of a series of rollers that rotate at different speeds, allowing the operator to manipulate the iron pipe and create a wide range of shapes and designs.

One of the key features of the hydraulic pipe twisting machine is its use of hydraulic power. This allows for greater precision and control in the shaping process, compared to traditional pipe twisting machines that rely on manual labor.

Additionally, the hydraulic pipe twisting machine is able to create more complex shapes and designs than traditional machines. This allows companies in the industry to produce a wider range of products and to meet the demands of a more diverse market.

2.3 How does the iron pipe stainless steel pipe tube drawing machine works?

The hydraulic round pipe twisting machine is composed of PLC control panel, hydraulic system and electric system.

PLC control panel: Control the machine through the program to select the pattern to be processed on the material, the length of the twisted pattern, and the depth of the twisted degree.

The hydraulic system mainly controls the linkage between the hydraulic cylinder and the mold. The hydraulic system provides power support to the mold to clamp and rotate the round tube, and cooperates with the pulling of the electric system to complete the processing of the round tube.

The electric system is responsible for dragging the round pipe to complete the processing of the pattern, ensuring that the colleagues who twist the round pipe in the hydraulic system can drag the round pipe at a stable and uniform speed

2.4 Benefits and advantages using a hydraulic pipe twisting machine in the wrought iron processing industry

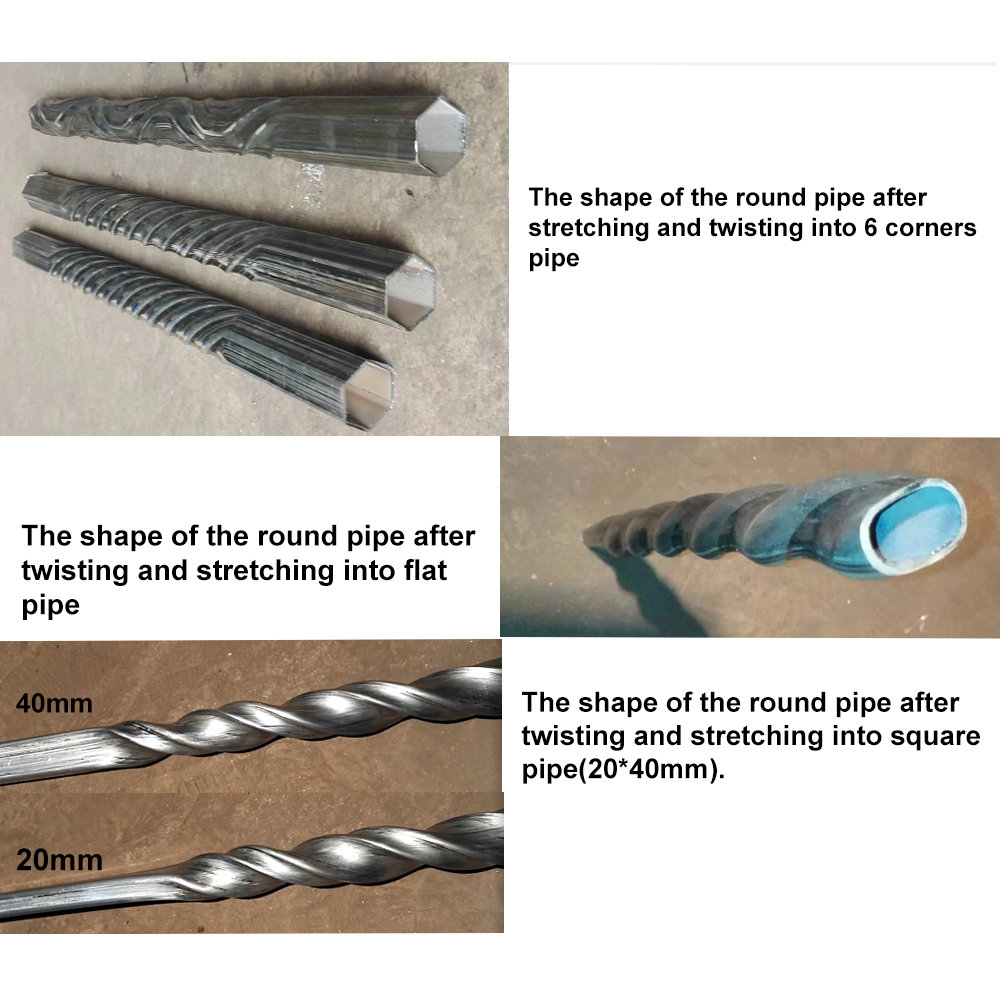

The hydraulic decorative iron pipe iron tube twisting machine is specifically designed to process round pipes. Its main function is to create various patterns on the round tubes, which are then used in the construction of railings, door and window frames, and handrails.

One of the key features of this machine is its use of hydraulic power, which allows for greater precision and control in the shaping process. It can create a wide range of shapes, including round pipes, square pipes, 6-corner pipes, 12-corner pipes, and 16-corner pipes.

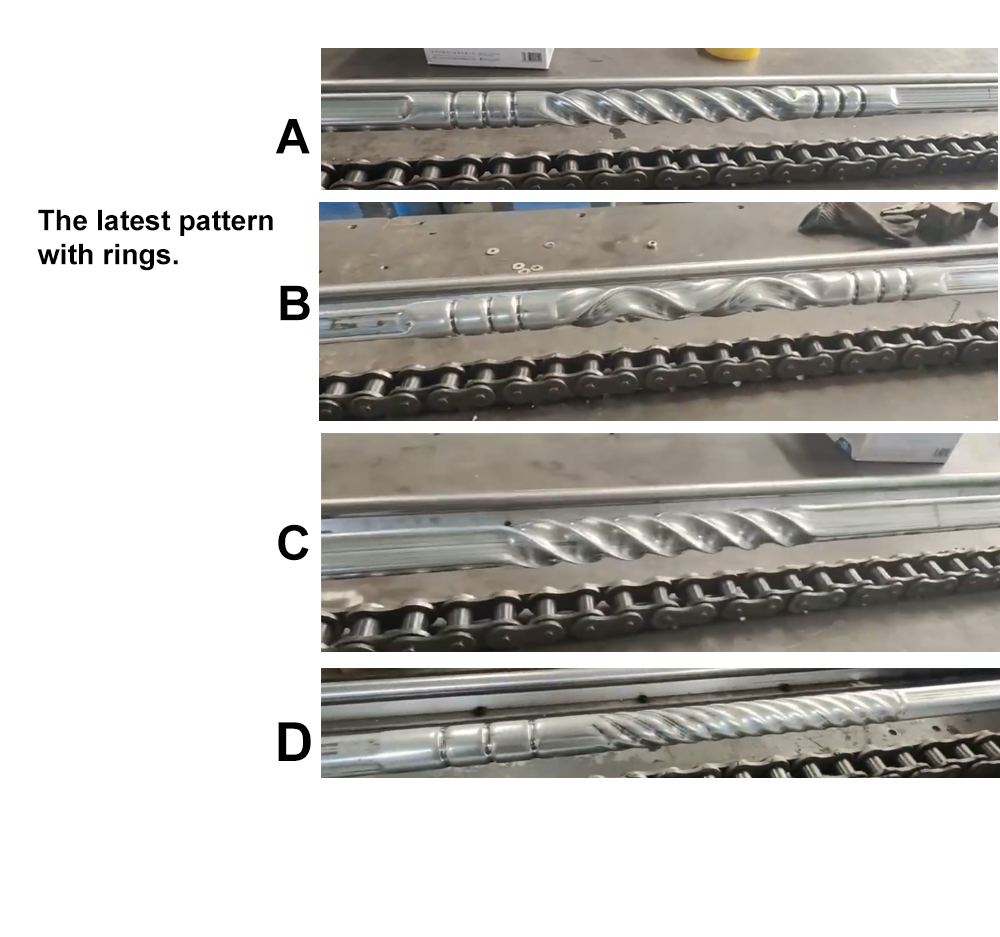

The LC120 hydraulic decorative iron pipe iron tube twisting machine is capable of producing a variety of pattern shapes by repeatedly twisting the round pipes. The density and depth of the patterns can be adjusted using the hydraulic system and limit switches.

Overall, this machine is an essential tool for blacksmith shops that produce doors, windows, and handrails on a large scale. Its ability to reduce costs by more than 50%-80% makes it a highly cost-effective option.

When using the LC120 hydraulic decorative iron pipe iron tube twisting machine, special attention should be paid to the thickness of the round tube. The machine is only capable of processing round tubes with a thickness of up to 2.5 mm.

LC120 Hydraulic Decorative Iron Pipe Iron Tube Twisting Machine

TECHNICAL PARAMETER

Model :LC-JKLG120

Processing material: Round tube≤Φ120mmx3mm

Dimensions of the finished product :

Round tube≤Φ120mmx2.5mm

Flat tube ≤ 90x60x2.5mm

Square tube≤40x40x2.5-90x90x2.5mm

Power: 11.7KW

For free dies :6sets

Voltage: 220V/380V/415V

Packing Dimension:800*1200*700mm

N.W. (kg): 2500 G.W. (kg): 2550

As an example, let’s consider the process of turning a round pipe into a square tube. The machine is capable of converting round pipes with diameters of 50 mm, 60 mm, 76 mm, 89 mm, and 114 mm into square pipes with sizes of 40 mm, 50 mm, 60 mm, 70 mm, and 90 mm, respectively.

It is important to note that the size and shape of the final product will depend on the diameter of the round pipe and the desired size of the square pipe. The machine’s hydraulic system and limit switches can be adjusted to produce the desired pattern density and depth.

3. How is an ornamental wrought iron round pipe twisting making machine different from traditional pipe twisting machines?

First of all, other machines for twisting square tubes are also developed by our factory.

Secondly, if we say that our hydraulic circular tube twisting machine has the following outstanding advantages compared with traditional machines

1. it has a large processing range and is capable of handling round pipes with a diameter of up to 114 mm.

2. There are many patterns to choose from, and the patterns are beautiful,

3. Free customized mold service, We also offer a free customized mold service for our customers. By understanding the different needs of our clients, we can design customized molds to meet their specific requirements.

4. Our machines are also known for their strong power and long life. They are built to withstand heavy use and can withstand the demands of the wrought iron processing industry.

5. Our machines offer a threshold for entry into the market. By purchasing one of our machines, customers can almost occupy the local market for such products. This can provide them with a competitive advantage and help them to grow their business.

4. Adoption of the hydraulic pipe twisting machine

Potential impact on the wrought iron processing industry.

Our machines offer a threshold for entry into the market. By purchasing one of our machines, customers can almost occupy the local market for such products. This can provide them with a competitive advantage and help them to grow their business.

In addition to the advantages mentioned above, our hydraulic circular tube twisting machine offers a number of other benefits for customers. For example, it is relatively easy to operate and requires minimal training. This means that even inexperienced workers can quickly learn how to use the machine and produce high-quality products.

Our machines are also designed to be energy-efficient. They use a minimal amount of electricity, which can help to reduce operating costs and improve profitability.

Finally, our machines are backed by a comprehensive warranty and technical support program. This ensures that customers can rely on us to provide the necessary support and service to keep their machines running smoothly and efficiently

5. Conclusion – Summary of the advantages of using a hydraulic pipe twisting machine in the wrought iron processing industry.

The use of a hydraulic pipe twisting machine in the wrought iron processing industry offers a number of advantages, including:

Increased precision and control in the shaping process

The ability to create more complex shapes and designs.

Improved efficiency and productivity.

Reduced labor costs.

Higher quality products.

The ability to meet the demands of a diverse market.

Energy efficiency.

Comprehensive warranty and technical support.