Why We Must Choose Electric Wrought Iron Machinery For Our Blacksmith Business?

Why We Must Choose Electric Wrought Iron Machinery For Our Blacksmith Business?

As an architectural decorative art, wrought iron art originated in Europe. It appeared in the early 17th century when the Baroque architectural style prevailed. The history, breathtaking, has been handed down to this day. In ancient Europe, it was only aristocratic culture, which appeared in the court and wealthy families, so wrought iron art was endowed with royal and famous style from the very beginning.

With the passage of time, wrought iron doors, windows, handrails and railings have entered the homes of ordinary people. The exquisitely crafted doors, windows and railings have been sought after by the public. Manual processing to make these doors, windows and guardrails has become less and less able to meet the huge product demand. The work of blacksmiths has also ushered in a change in power. Electric and hydraulic wrought metal machinery has emerged to assist the work of blacksmiths.The improvement of production efficiency and output is obvious to all.

Why do we say that electric wrought iron machines are very necessary for blacksmiths?

1.Purely handcrafted metal can no longer meet the huge demand for metal forging products in the market.

The manual processing speed is far from meeting people’s requirements for delivery time, let alone the production requirements of batch orders. Using the high efficiency of machines to assist labor is more effective.

2.Electric wrought iron machinery can better control the time cost of the blacksmith shop

2.1. If it is a small courtyard door, window, railing and garden wrought iron, it may take a blacksmith for a week. If your blacksmith has a complete set of electric wrought iron machinery, one week is enough for you to receive orders for 100 courtyards.

2.2.With the increase of labor cost, labor cost is a large proportion of store operating expenses that you have to calculate. The application of electric forging machinery can not only reduce labor occupation but also produce large-scale and standardized products in the shortest time. How to efficiently control labor costs will be the golden key for your smithy to create higher wealth.

3.The wrought iron products produced by the machine are more beautiful, exquisite and uniform in specification.

The wrought iron machinery with a well-set program can produce forging elements with uniform specifications for the manufacture of doors, windows, railings, green fences, and home furnishing.

The size adjustment of wrought iron elements can be realized by adjusting the processing time of the program codes or replacing the mold of machine.

4.It only takes 10 minutes to skillfully operate the electric wrought iron forging machine.

The machine has a control panel, and it is not difficult to operate the machine and mass-produce products by setting different program codes.The machine is equipped with instruction manual and operation video, it is easy to learn.

5.Electric wrought iron equipment comes with a variety of free molds.

All forging machines are equipped with free moulds. The number of moulds is different according to the function of the machine. For details, please send inquiry to us.

6.The replacement of electric wrought iron equipment mold usually only takes 5 minutes.

Different molds can process wrought iron elements of different sizes, and the replacement of molds is very simple, and most molds can be replaced within 5-10 minutes.

7.We provide free mold design services to make customers’ products more unique.

Some customers want to customize molds suitable for their own material sizes, and they want to customize their own unique patterns, or have some difficulties encountered in forging career that have not been solved, and they can tell us. We have a professional technical team to design mold drawings and technical breakthroughs for you free of charge. Looking forward to your inquiry.

8.The application of electric wrought iron equipment allows you to process more materials and reduce material costs.

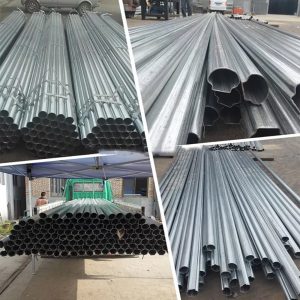

For example, ordinary blacksmiths can only process square steel, flat iron, round steel and other materials. The fishtail machine, scroll bending machine and hydraulic forming machine produced by our factory can process square pipe, round pipe and stainless steel pipe. When making doors and windows, the solid square steel material becomes a hollow square tube, which reduces a lot of material costs and makes the doors and windows lighter and more beautiful.

We have a special handrail tube processing machine specially used to process round tubes to become stair handrail tubes, and stair railings can also be made of round tubes and square tubes by pipe twisting machine, which are very beautiful and unique in shape.

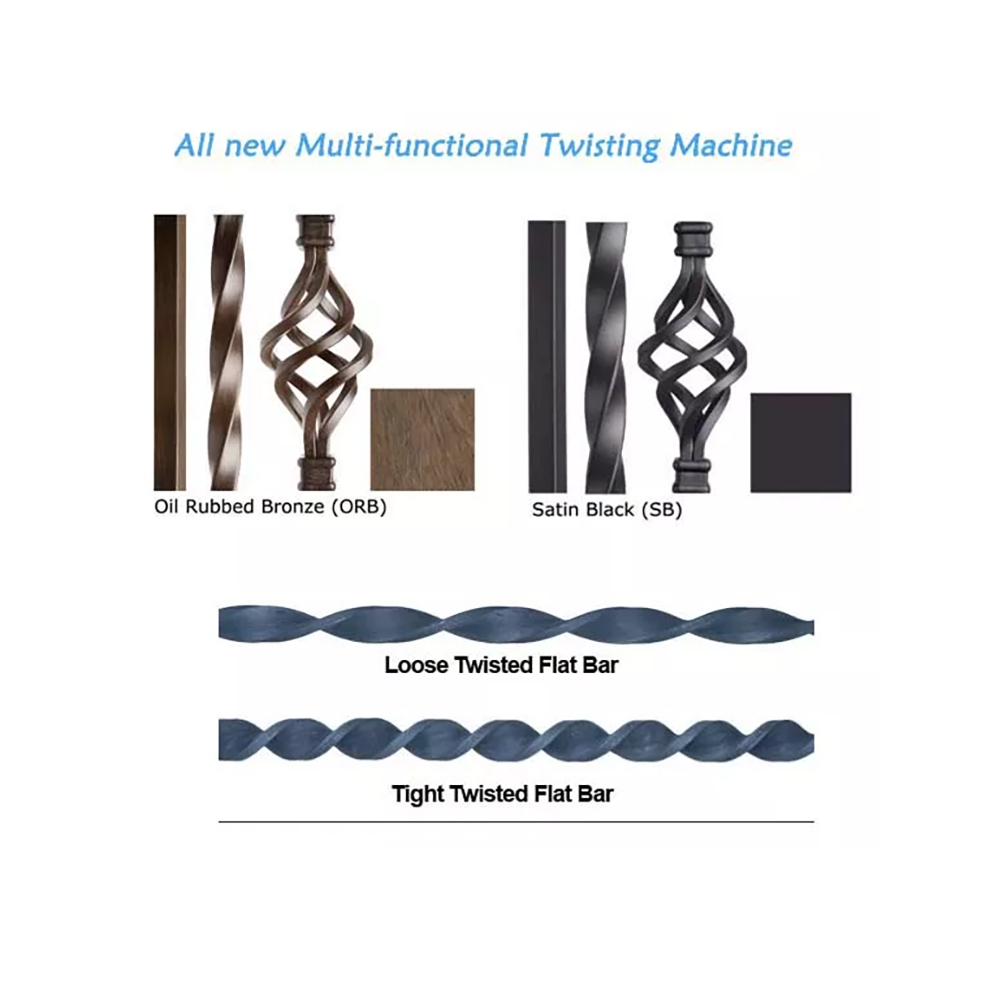

There is a basket-shaped stair railing that is very beautiful in shape, and the twisting machine used to make birdcages is also our special machine.The batch processing and production of these materials cannot be done by manual hammering of metal.

9.Electric wrought iron machinery already has an equipped production line for the smithy business.

After more than 20 years of development, the electric wrought iron production machinery has a mature technology to meet various production requirements of customers, even several different functions can be installed on one machine, and we can adjust the machine according to the customer’s budget If you have such a production line, it will create wealth for you like a money printing machine.

10.What are the electric wrought iron metal forging processing machines?

As we all know, when we usually make door, window and railings, we often process square steel, flat iron, square tube, and round steel into C, P, and S shapes, and even need to press out various shapes on the metal surfaces of C, P, and S shapes. Various patterns and pressing specific patterns and shapes on both ends of C, P, S shape metal.

And our forging equipments can meet your needs to simplify the cumbersome process, and complete batch orders in a short time.You can first know the functions of these iron forging equipments and choose the equipments you think are necessary according to the functions you need.

10.1 Power of iron effcient heater

The high-frequency heating machine can quickly heat the metal, which is very suitable for the high-frequency and high-efficiency work rhythm of the blacksmith shop, But this machine saves electricity!!

10.2 Electric wrought iron scroll bending machine

This electric scroll bending machine can process and bend “p” patterns with a maximum diameter of 1.5 meters. It can bend square pipes up to 45x45mm.

Available materials are: square steel, flat iron, round steel, square tube, round tube.

10.3 Wrought iron cold rolling embossing machine

This machine cold-presses the pattern you want on flat iron, square steel, round steel, round pipe, and square pipe.

We provide customers with mold pattern design services for free!!

10.4 Wrought iron twisting machine

This machine can not only twist square steel, flat iron into twist shape,

but also can twist 4-wire flower basket, 8-wire flower basket, 12-wire flower basket!!!

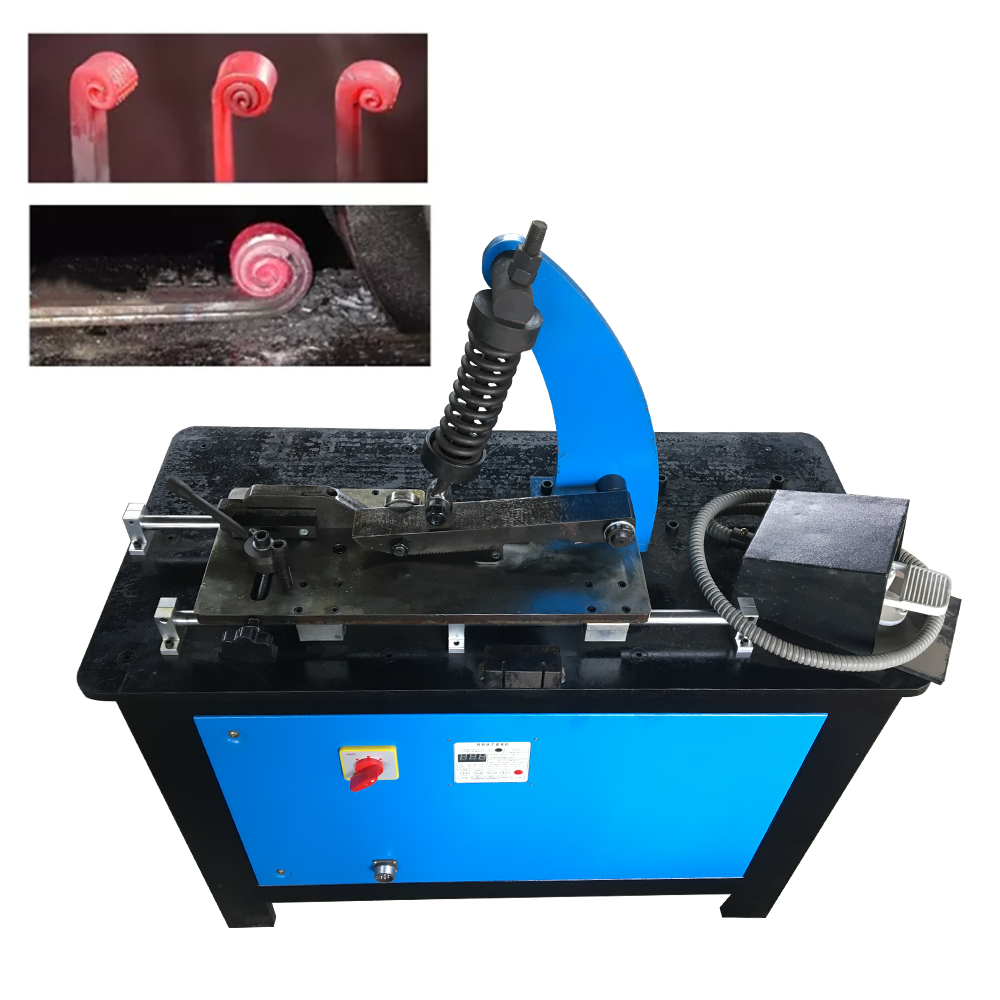

10.5 Hot Metal Electric Iron Coil Making Machine For Wrought Iron With Factory Price

This coil making machine can roll the end of the square steel , flat iron and round steel into the shape of a snail shell! ! Formed in one go!

10.6 Electric Decorative Metal Craft Wrought Iron Fishtail Making Machine

This fishtail making machine can presses the end of flat iron, square steel and round steel into the shape of fishtail, the shape is very beautiful!

A variety of patterns for customers to choose!

10.7 Wrought Iron Hydraulic Moulder Machine For Metal Craft

This professional hydraulic moulder can cold-press flat steel & square steel , and four sets of free molds are randomly selected for customers. The finished products are mostly used in fences and windows, and are deeply loved by customers because of their luxurious and beautiful styles!

New function: This machine can process square tube.

10.8 LC-C3 Electric Hydraulic Pipe Bender Manufacturers & Suppliers

This pipe bending machine is professional in bending square and round pipes.

The machine is available in both hydraulic and electric versions

10.9 Aotumatic Multi Function Round Pipe Twisting Machine

This machine is a professional machine for twisting round pipes.

The maximum processing diameter is 114mm round pipes.

The finished products are widely used in door and window frames and railings.

10.10 Air hammer for wrought iron

The air hammer does not require the customer to prepare an air compressor separately, and it can be used when it is powered on!

6KG-1000KG different air hammer models are available, it is a necessary machine for free forging.

If you have any questions,please feel free to contact with us!!