C41-400KG China Biggest Hammer Manufacturer Provide Pneumatic Forging Hammer

This C41-400KG China biggest hammer manufacturer provide pneumatic forging hammer converts the rotational motion of the motor into the piston motion of the cylinder compressed air by the reducer, crankshaft and connecting rod system. The air hammer is controlled by the foot lever and the remote control device to control the hitting speed and hitting strength of the upper anvil.

Pneumatic hammer machine is a widely used and versatile metal forging tool, which has many functions, such as: upsetting, extending, continuous upsetting, stamping, hot cutting, welding forging, twisting and bending.

Customers can choose the air hammer that suits them according to the material they need to forge and the maximum size of the material. The application of electric power and cylinder greatly improves the working efficiency of the air hammer. It is essential for the operation of blacksmith shops and mines. forging machinery.

We can supply 6 kg, 16 kg, 25 kg, 40 kg, 55 kg, 75 kg, 100kg,150 kg, 250 kg, 400 kg, 560 kg, 750 kg, 1000 kg, 2000 kg for choose according different forging work need.You can choose the model according by the following specifications

TECHNICAL PARAMETER

Model:C41-400KG

Falling parts weight(KG):400KG

Structure type:Split Air Hammer With Base

Max.Hit energy(KJ):9.5KJ

Max.forged size(diameter) on Round steel:φ240mm

Max.forged size(diameter) on square steel:220*220mm

Power: 37 KW

Voltage: 220V/380V

Packing Dimension: 2785*1400*2885mm

Navil weight:4800KG

Total G.W. (kg): 12800KG

Inquiry

Description

C41-400KG China biggest hammer manufacturer provide pneumatic forging hammer

Pneumatic air hammers for blacksmith are divided into 6 kg, 16 kg, 25 kg, 40 kg, 55 kg, 75 kg, 100kg, 150 kg, 250 kg, 400 kg, 560 kg, 750 kg, 1000 kg, 2000 kg according to the weight of the falling parts of the air hammer .

According to the structure, the air hammer can be divided into three types,Customers can choose air hammers with different structures according to their needs:

1.single air hammer,

2.split air hammer,

3single air hammer with base.

Both the single air hammer and the split air hammer need the customer to lay the foundation for the machine by himself, and the drawings of the foundation and the points that need to be paid attention to will be sent along with the machine.

The single air hammer with a base is directly equipped with a base without the customer needing to lay the foundation for the machine, and it is easy to carry and can be transferred to the workplace at any time, which is very suitable for customers who often need to change the construction site.

This 400KG air hammer is a separate structure.

The transmission mechanism of blacksmith forging hammer includes reducer, crankshaft and connecting rod system. It transforms the rotary motion of the motor into the up and down reciprocating motion of the compression piston. The belt pulley is driven by the motor and fully rotated. It is equipped with foot lever for better forging.

C41-400KG AIR HAMMER

| Pneumatic air hammer forging machine | |

| Model | C41-400 |

| Falling parts weight(KG) | 400KG |

| Height of working area | 530mm |

| Max.Hit energy(KJ) | 9.5 |

| Hit frequency(min-1) | 120 |

| Max.forged size(diameter) on Round steel | φ240 |

| Max.forged size(diameter) on square steel | 220*220mm |

| Motor(KW) | 37 |

| Motor Speed(r.p.m) | 1480 |

| Overalldimensions (L*W*H) | 2785*1400*2885mm |

| Navil base weight(KG) | 4800 |

| Total weight(KG) | 12800 |

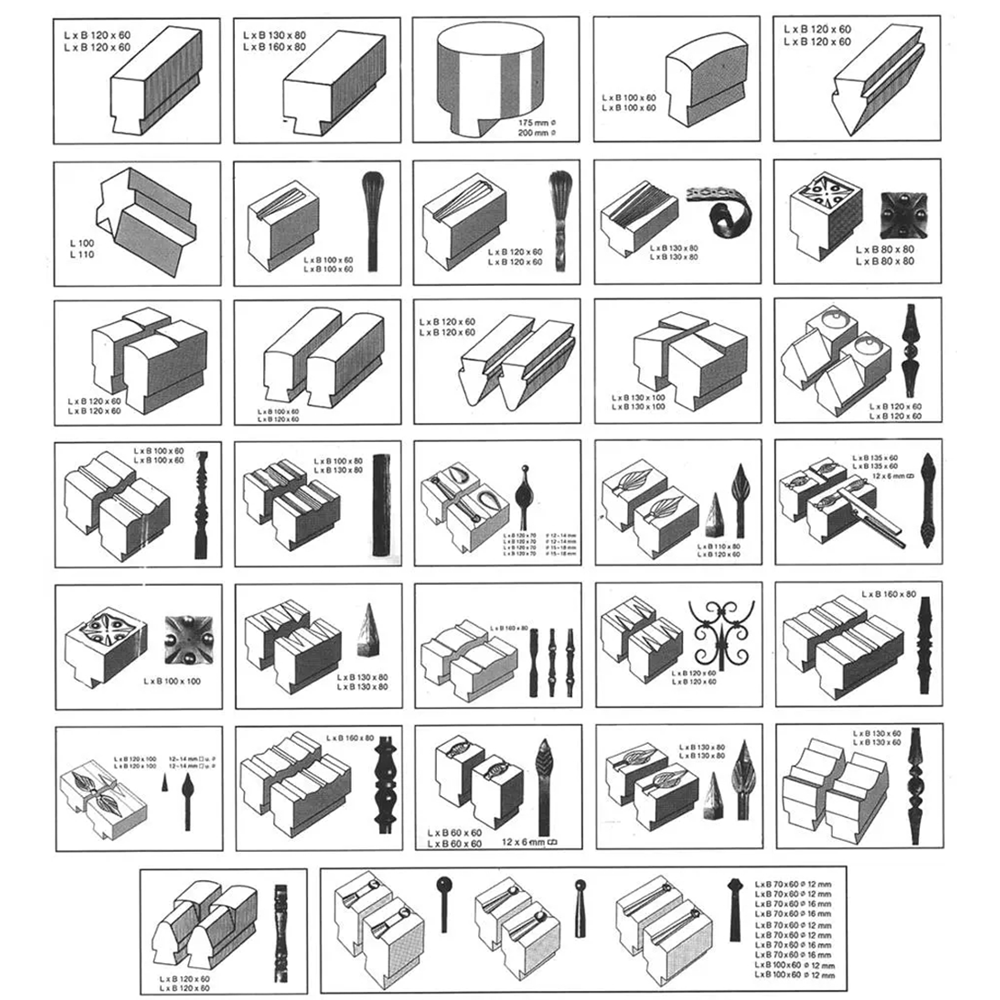

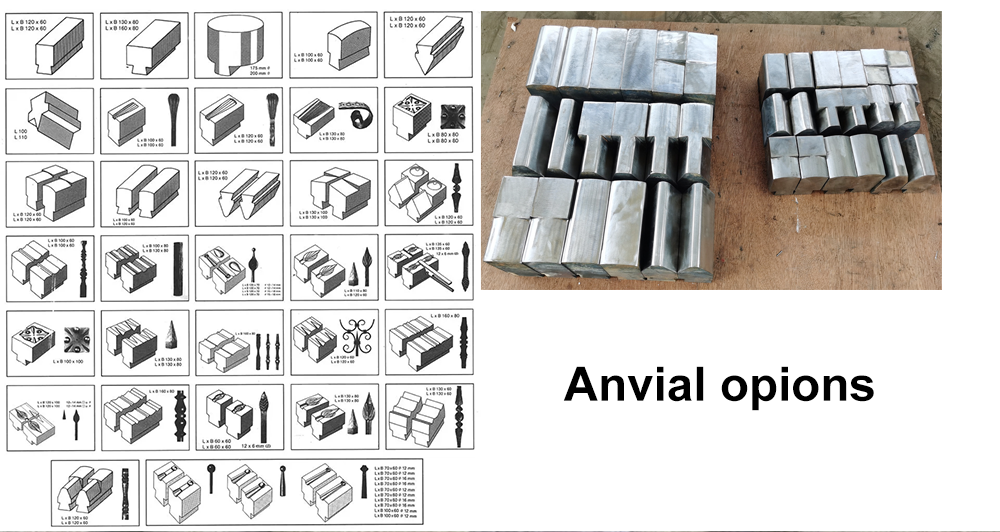

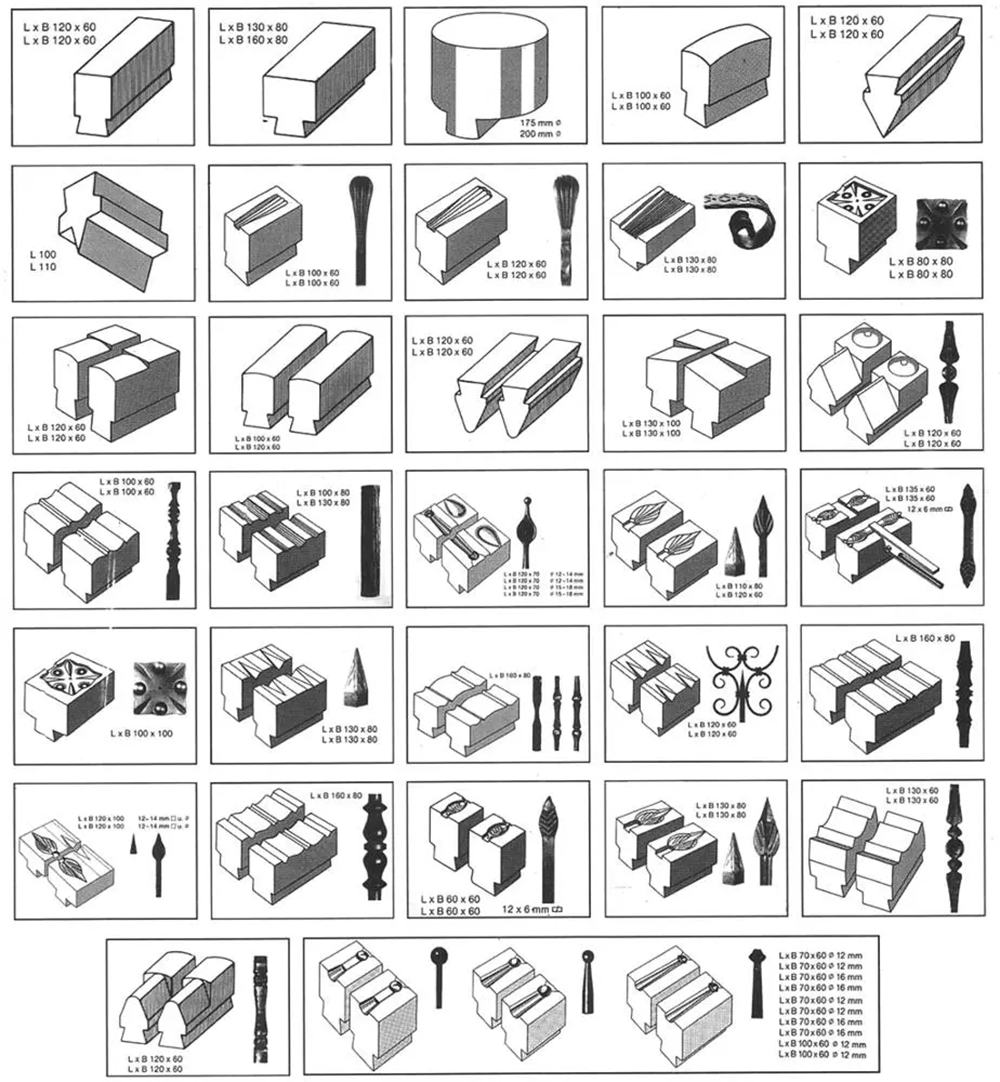

Forging hammer anvil base.

The forging hammer anvil can be customized free of charge according to the needs of customers. The lower anvil is installed on the anvil base. In order to meet the stability of the overall machine during forging, the weight of the anvil is required to be 12-15 times the weight of the falling part. C41-560KG This level of air hammer has two styles: separate air hammer and separate air hammer with base. The needle seat of the split air hammer is fixed on the cement foundation. The customer needs to make the cement foundation according to the drawing, and the gap between the anvil and the machine body Gap-filling wooden sticks, which can eliminate vibration caused by hammering.Customers can also choose separate air hammer with base according to their needs.

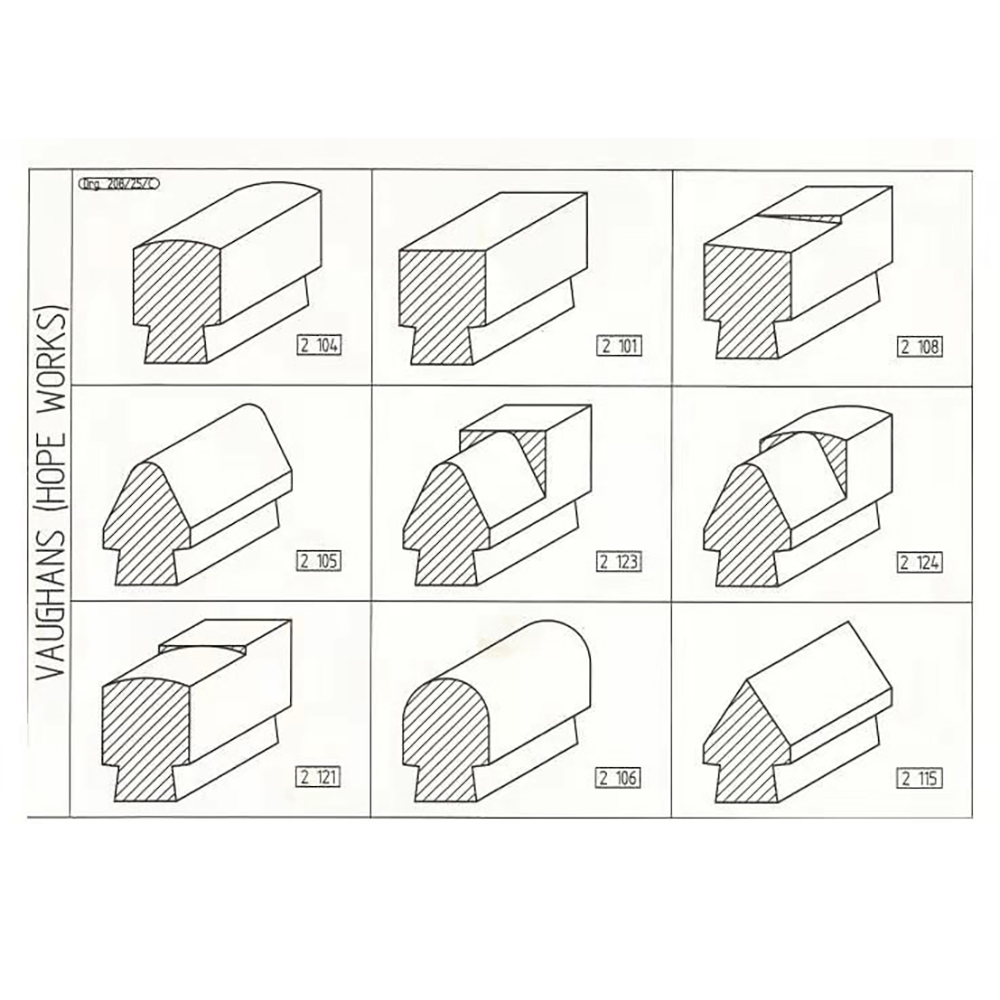

Customized Anvil Of Forging Hammer?.

The anvil is divided into upper and lower parts

The anvil of the forging hammer can be selected according to the material and size of the forged product. We will provide drawings of conventional anvils for customers to choose, and customers can also customize their own anvils according to their needs. This can largely meet the needs of customers forging metals of different shapes.

Finished products

Functions

C41-400KG China biggest hammer manufacturer provide pneumatic forging hammer price

Main Features

main feature

1) The air hammer is simple in structure and easy to operate, and the customer does not need to prepare an additional air compressor.

2) Advanced resin casting hammer frame and other components are used to make the casting surface very smooth.

3) Easy installation and easy maintenance.

4) The operation is simple, the handle and the pedal control the work of the air hammer.

5) Provide 1 year spare parts instead of wearing parts

6). Random set of free hammer molds, we can design and customize hammer molds for customers free of charge.

7).Provide mature, stable and cheap shipping agency.

Die Options

C41-400KG China biggest hammer manufacturer provide pneumatic forging hammer

One set die comes with machine for free.Customers can also choose other dies, we provide free design and custom mold services.

Customers need to provide the maximum size of the material to be processed and the name of the material, we can provide customers with free block design services and recommend the most suitable air hammer model.

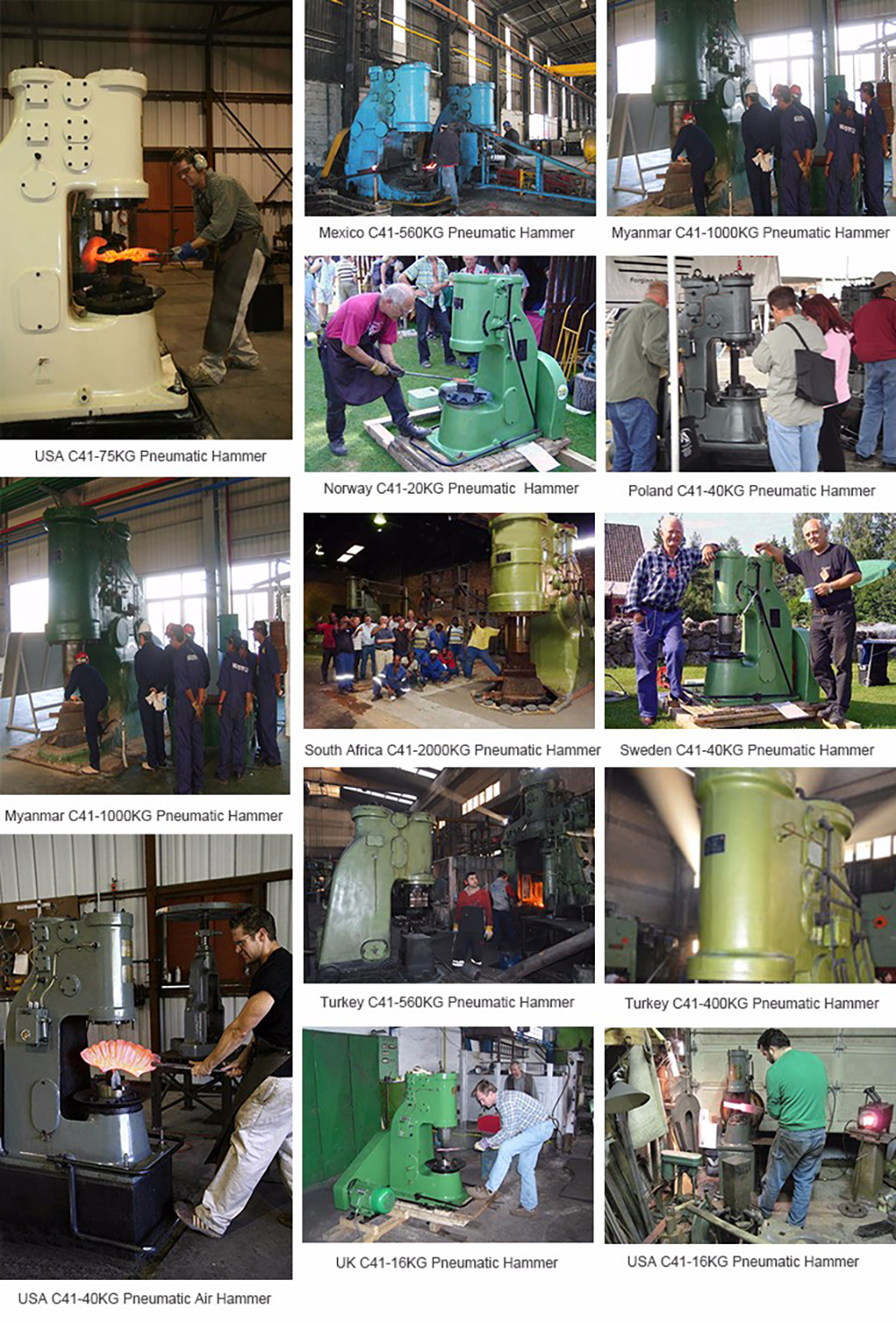

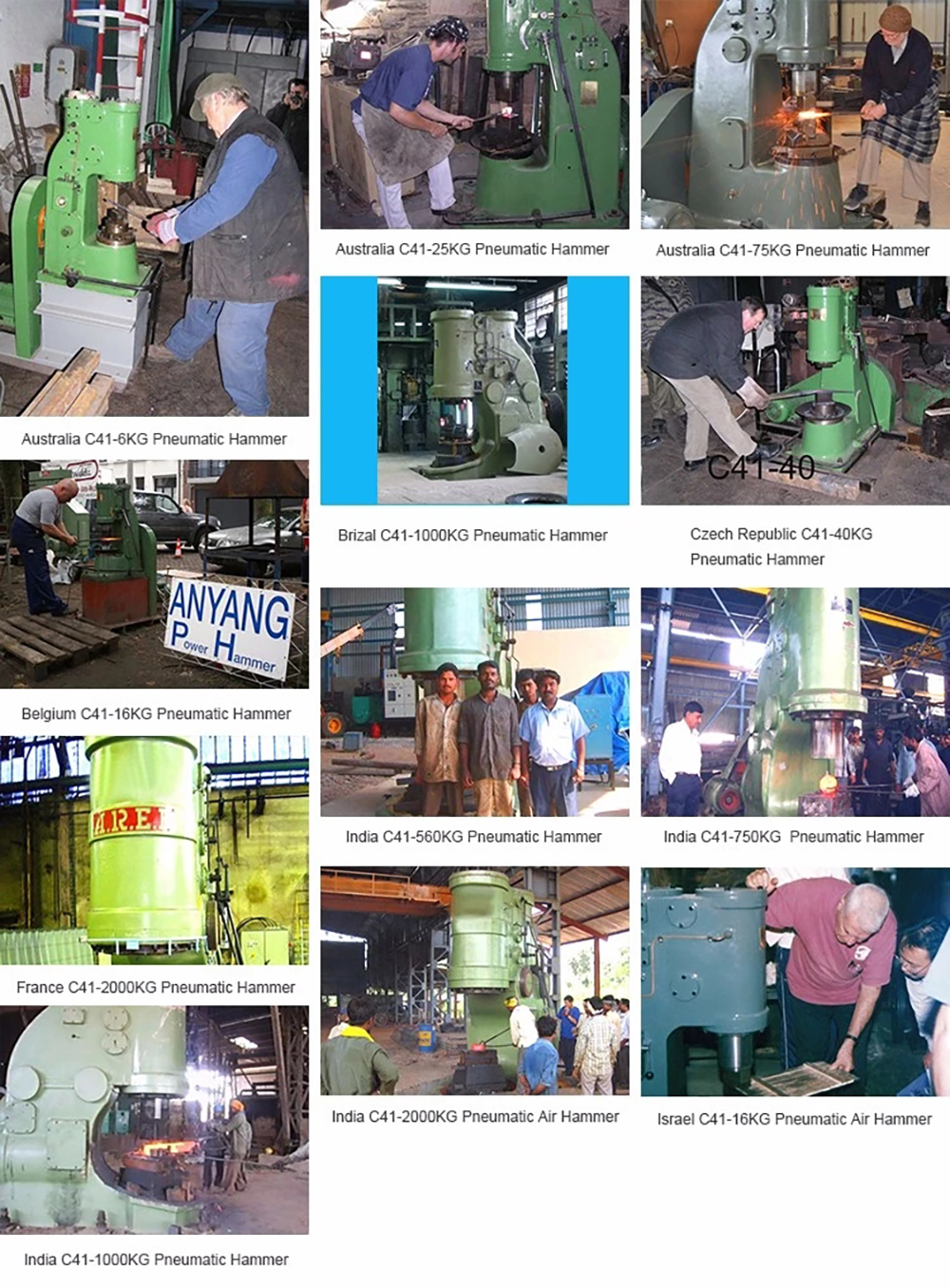

Feedback

Packaging

Packaging standard:

Dust cover + iron frame + wooden box packaging.

Mode of transportation: By car or by sea.