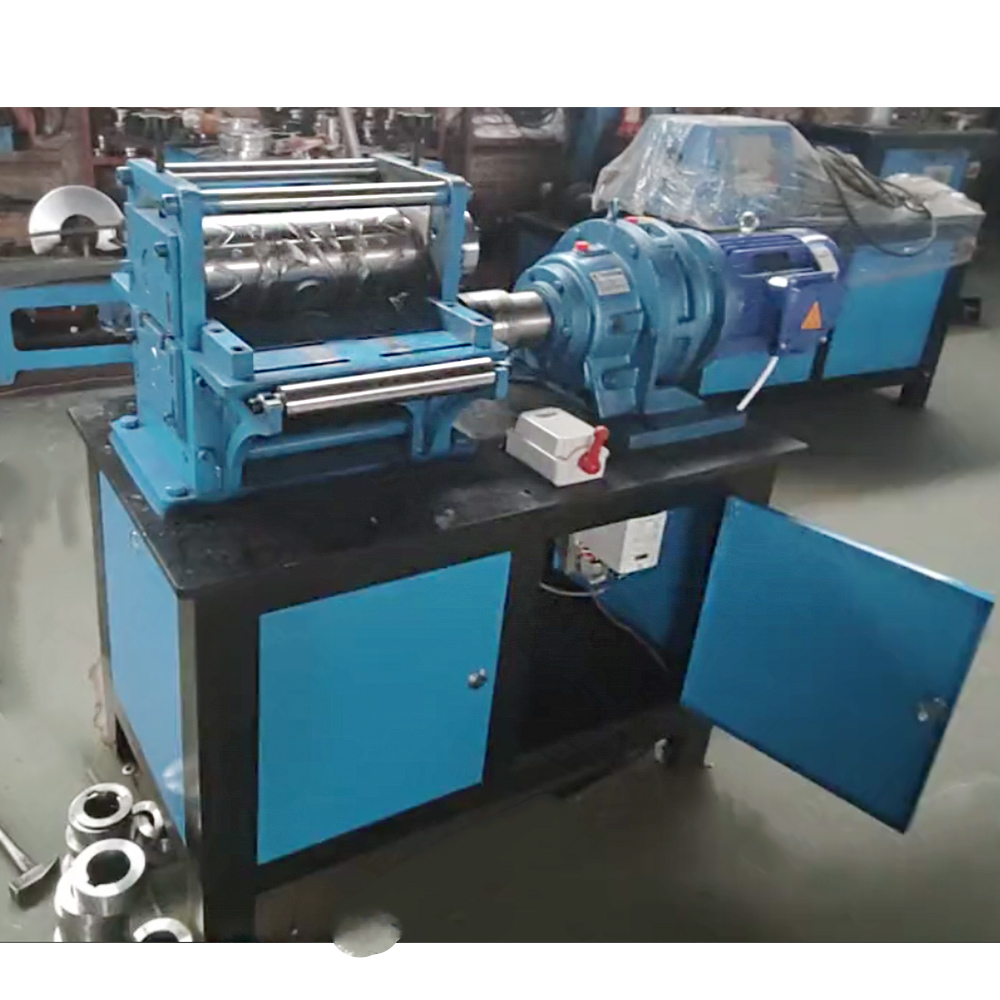

JK-300 Factory Directly Automatic Metal Sheet Embossing Machine

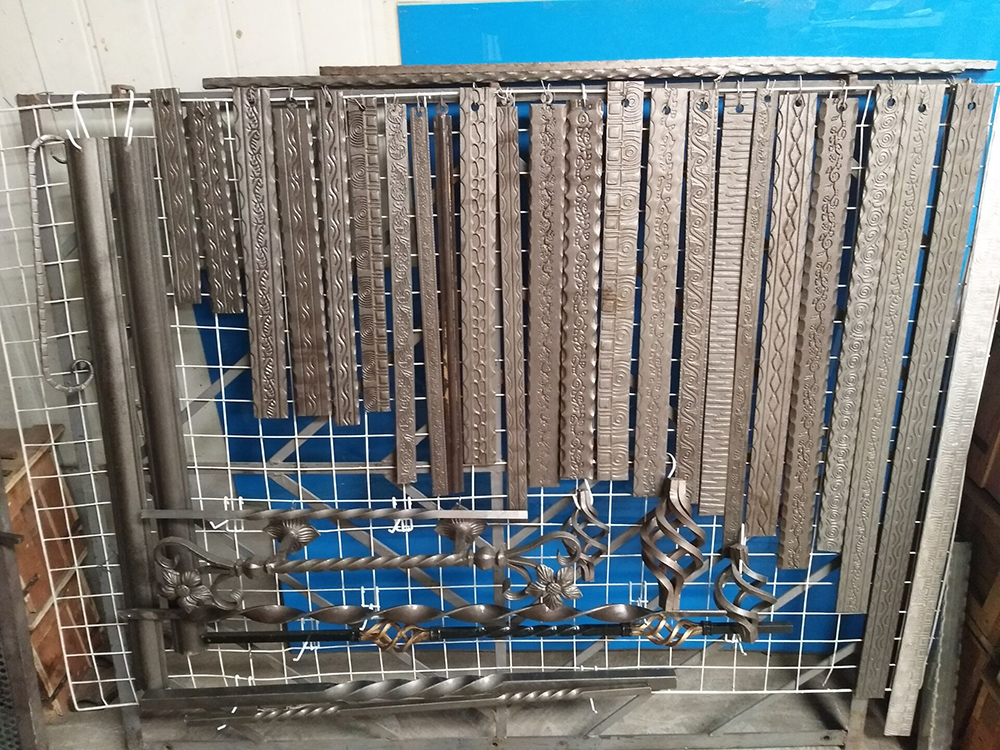

This JK-300 Factory directly automatic metal sheet embossing machine can process cold-rolled sheet iron plates, sheet aluminum plates, sheet stainless steel plates, and sheet copper plates for the patterns customers want. A set of mold is randomly comes with the machine. Our technical team can provide free custom design services for molds. A variety of pattern choices will definitely allow customers to compete in the fierce local market. It stands out from the competition because of its unique pattern.

The processed finished product can continue to be stamped into the shape that the customer wants for the door frame frame, grille, window frame, door panel, green railing, etc. All can be used in thin iron plates with patterns.

TECHNICAL PARAMETER

Material: Iron sheet, Aluminum sheet, Copper sheet, Stainless steel sheet

Material width:300mm

Material thickness: maximum 2 mm

Power: 4KW(According to the width and thickness of the rolled material according to the actual needs of customers)

Voltage: 220V/380V/415V

Packing Dimension: 1500×710×800mm

N.W. (kg): 350

G.W. (kg): 400

Inquiry

Description

JK-300 Factory directly automatic metal sheet embossing machine

Metal plate embossing is a kind of cold rolling process. The mold consists of the upper and lower pairs of rolling axis. The gap between the molds between the molds is instant thin iron plate, the thin aluminum plate, the copper plate, and the thin stainless steel plate. different patterns can be pressed on the sheet iron plate by replacing different molds.

What are the advantages of using sheet iorn plate cold embossing machine?

1.Sheet iron plate cold embossing machines are used to create embossed patterns on sheet metal. Some advantages of using this type of machine include the ability to create intricate and detailed designs, the ability to create a consistent and uniform finish on the metal, and the ability to produce large quantities of embossed metal quickly and efficiently.

2.Additionally, cold embossing sheet does not require the use of heat, which can be beneficial for delicate or heat-sensitive materials. Overall, cold embossing is a versatile and effective technique for creating decorative patterns on sheet metal.

3.We provide customers with free mold design services to suit the size of the customer’s material and the pattern the customer wants.

4.The machine has two upper and lower moulds, which are driven by the motor and reducer to roll. The two moulds squeeze the metal sheet sandwiched between the rollers, and machine will cold press the patterns of the rollers on the metal sheet.

5. The tickness of the sheet iorn up to 2mm.

6. The metal sheet that can be cold processed can be iron sheet, copper sheet, aluminum sheet, stainless steel sheet,

7. Processing speed can be adjusted.

The scope of use of the finished product:

It can be the edge decoration of the door frame, or the decoration of the advertising frame. Components made of doors and windows, or other places where embossed iron plates are required.

Functions

The functions of JK-300 Factory directly automatic metal sheet embossing machine

1.The machine has two upper and lower moulds, which are driven by the motor and reducer to roll. The two moulds squeeze the metal sheet sandwiched between the rollers, and machine will cold press the patterns of the rollers on the metal sheet.

2. The tickness of the sheet iorn up to 2mm.

3. The metal sheet that can be cold processed can be iron sheet, copper sheet, aluminum sheet, stainless steel sheet,

4. Processing speed can be adjusted.

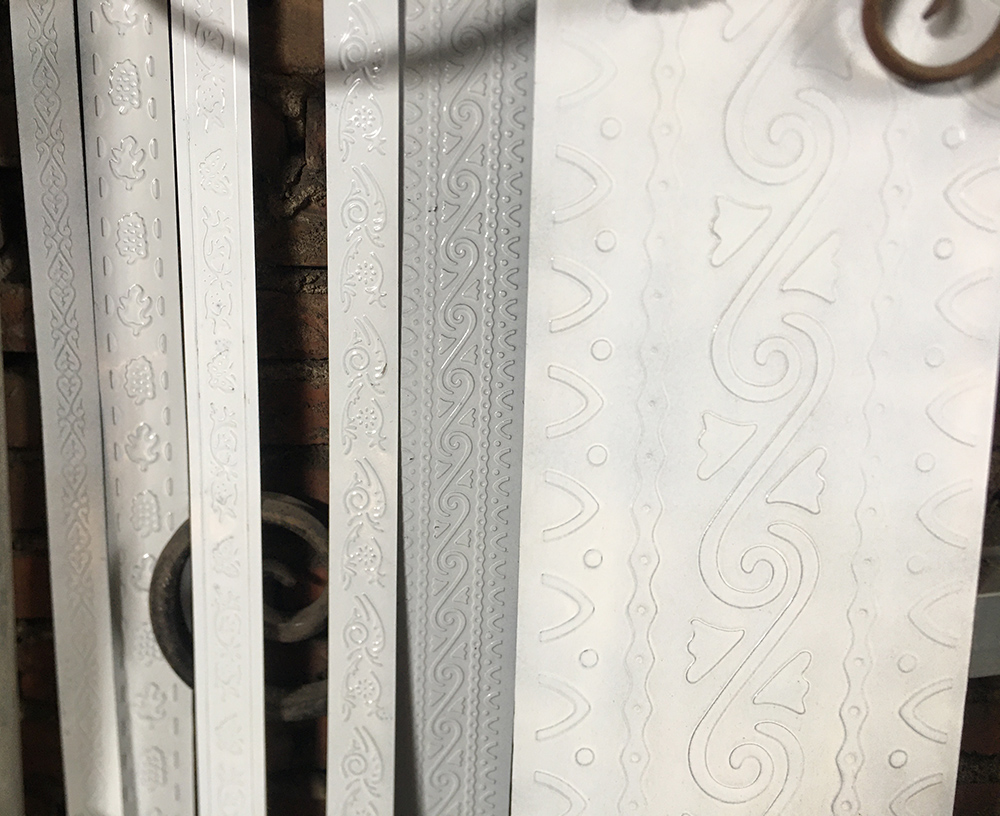

Finished Product

JK-300 Factory directly automatic metal sheet embossing machine.

The appearance of the material after it has been processed by the hydraulic cold rolling metal wrought iron embossing machine.

Packaging

Packaging standard:

Dust cover + iron frame + wooden box packaging.

Mode of transportation: By car or by sea.